- Show results for

- Share

Choose the Best Plasma Cutter for a Beginner

- Introduction

- What is a Plasma Cutter?

- The Working Principle of a Plasma Cutter

- Types of Plasma Cutters and Their Application

- Technologies used in plasma cutters

- Choosing the best plasma cutter

Contents:

Introduction

Plasma cutters are used in various industries, including the automobile manufacturing industry, shipbuilding, construction, the list goes on. These tools can also come in handy if you are a sculptor or a designer, as they allow you to create complex shapes. No matter what the application is, you want a reliable instrument that does its job. Keep reading and learn how to choose the best plasma cutter if you are a beginner.

What is a Plasma Cutter?

First things first, let’s define plasma. In short, it is a state of matter, an ionized gas-like substance that is electrically conductive.

A plasma cutter is a special tool that is used to cut through electrically conductive metals. It can pass through an array of metals, for instance, aluminum, brass, steel, the list goes on.

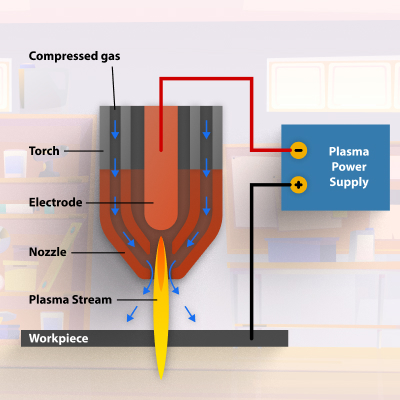

The Working Principle of a Plasma Cutter

Nowadays, you can choose from a wide range of plasma cutters, they have different sizes and shapes, however, their working principle is the same.

These tools utilize a plasma stream to transfer energy to a conductive work material. They send an electric arc through a gas that is passing through a constricted opening. In the center, there is a negatively charged electrode. The connection creates a circuit when power is applied to it & the operator touches the tip of the nozzle to the metal. After that, a spark is generated between the electrode and the metal. The inert gas passes through the channel, as a result, this spark heats the gas until it becomes plasma, which conducts electrical current.

Types of Plasma Cutters and Their Application

Classification

By Cutting Type

- For manual cutting - as a rule, these instruments are handheld and compact, as a result, they are perfect for personal use.

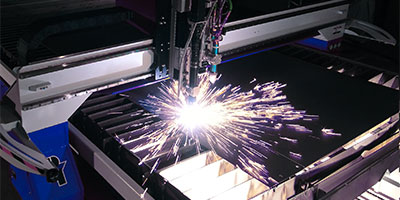

- For automatic cutting - such instruments are great for industrial use & heavy-duty applications.

By Gas Type

- Using compressed air - this is the most popular option. Such plasma cutters have a simple construction, they are affordable and easy to operate.

- Using argon, nitrogen, or oxygen - these tools are utilized in complex systems.

By Arc Ignition Type

- High Frequency Arc Ignition - an HF arc is used to jump the gap between the plasma electrode and the tip, allowing the main arc to form across the high frequency arc and the cutting to start.

- Contact Arc Ignition - the plasma electrode and the tip are kept in contact with each other by the torch head. When the operator wants to start cutting, the torch trigger is pressed and the machine delivers a small amount of power. Meanwhile, a pneumatic piston uses compressed air in order to pull the plasma electrode and the tip apart. Then, the machine delivers full power to start the arc.

By Cooling Type

- Air cooling - the nozzle is cooled as the working gas or air goes through it.

- Liquid cooling - it is necessary for the cooling of powerful machines.

Application

Plasma cutters can be used only for conductive metals & alloys, for example:

|

|

|

Spheres

Art

For metal artwork, artists can use these instruments in order to make precise cuts. A plasma cutter allows you to cut out complex shapes. The tool will also come in handy if you want to create a template or a stencil.

Contractor & Trade Work

Due to the compact size and portability of these tools, they can easily be used in the field. A precise cut is just what you want when you need to save some time, in addition, with immediate adjustments that are done onsite, the job will run smoother.

Metal Repairs

A good plasma cutter will come in handy for car repair, racing, demolition derby enthusiasts as well as farmers, and so on.

Demolition & Recycling

This instrument also allows you to achieve the results you want when working with various metal sheets, blocks, and metallic pipes during demolition. Your working space will be much cleaner (than if you use other methods).

Technologies used in plasma cutters

Today’s equipment incorporates advanced technologies. For example, inverter plasma cutters allow for a high frequency arc start or pilot arc that can jump start the plasma before jumping the gap from the torch tip to the work surface. Using an inverter plasma cutter is cost-effective, it can cut metal details up to approximately 1" thick. A transformer plasma cutter can cut metals up to approximately 3" thick, it is a bit more expensive. Note that an inverter is much more compact and lightweight than a transformer.

At Prime Buy, you can choose from various inverter plasma cutters that offer excellent cutting performance. They are suitable for industrial and construction work & for home use.

Choosing the best plasma cutter

First, you need to figure out what type of work you need a device for, know the thickness of metal, etc.

Here’s a short list of things to consider:

- Cut Capacity - the higher the amperage output, the thicker the metal they can cut.

- Cut Quality - look at the models that offer clean as well as fast cuts.

- Voltage - there are three main voltage options: 115V, 230V, and dual voltage. 115V is ideal for beginners who are using a standard home outlet, however, if you are looking for a machine with more power for professional use, you may want 230V.

- Duty Cycle - the duty cycle of your plasma cutter means how long it can be used continuously at maximum voltage. The higher the duty cycle is, the longer your tool can be used without having to rest.

- Pilot Arc - with a special pilot arc feature, you will cut metal with a higher degree of precision with a more stable arc. You will also be able to cut through more types of metals.

|

| Amico Plasma Cutters |

| View Details |

If you decided to buy a reliable device that will stand the test of time, pay attention to Amico Electric plasma cutters. They are easy to use.

The CTS-160 plasma cutter and the CTS-200 3-in-1 combo welding machine are great for hobbyists and welding enthusiasts who have basic repair needs & general light welding requirements.

The CUT-30, CUT-40, and CUT-50 are plasma cutter machines that have the meter and adjustment attached to the front of the device and the filter that is located inside the machine. The units are perfect for portable repair work as well as small business project use.

The APC-40HF, APC-50HF, APC-60HF, and APC-70HF have the instrument and air pressure regulator installed inside the machine on the panel. The air filter is installed in the machine and is controlled automatically by a solenoid valve, which enhances the work efficiency.

On our website, you can also purchase Wizard Plasma Burning Guides from Flange Wizard (for straight and radius cuts + hole burning) or, for instance, a Plasma Wiz with Bushing (to cut holes in metal effortlessly).

Get the right product for your application!