Walchem, EWN-C16TCUY-1, EWN-Y Series Electromagnetic Metering Pump, 24W, 15mm Diaphragm Diameter, PVDF, 115V US Plug, EFS-XX-FT Sensor

Features:

- High Speed Performance. E-Class pumps operate at 360 strokes-per-minute, providing high resolution chemical feed. Most competitive products operate at slower speeds, resulting in slug feeding, accelerated diaphragm wear and poor feed control.

- Engineered Longevity. All E-Class pumps feature dual bearing support. The armature and shaft are supported with a bearing on each end, which ensures proper axial movement, enabling the E-Class to operate at 360 SPM while extending the life of the diaphragm.

- Superior Check Valve Performance. Dual Check Valve Assemblies in both suction and discharge fittings feature precision ball guides and tapered seats. Precise machining and molding of parts limit valve ball travel, ensuring that balls fully seat and seal with every stroke. This superior check valve design guarantees fast priming and reliable performance.

- High Compression Ratio. The compression ratio of a metering pump is important because it affects the pump's ability to prime and vent. The compression ratio is raised when you reduce the dead volume of the pump head during operation. All E-Class pumps feature a very high compression ratio that ensures proper feed especially with off-gassing products (i.e. Sodium Hypochlorite).

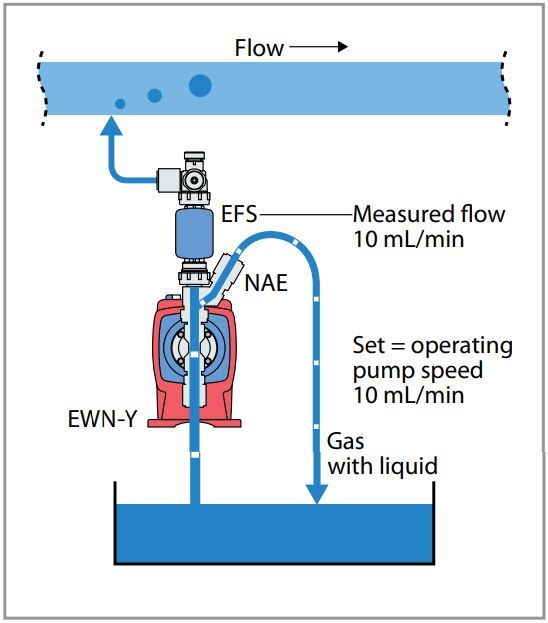

Iwaki's EWN-Y Series Electromagnetic metering pump with the revolutionary EFS Flow Sensor provides precise flow monitoring, feedback and control. The EWN-Y electromagnetic pump combined with EFS flow sensor provides accurate real-time control and display of dosing rate. Set point control allows the desired flow rate to be simply programmed into the pump. Through feedback from the EFS sensor, the pump constantly adjusts its speed to maintain the set dosing rate - even under changing temperature, viscosity or suction and discharge pressure conditions.

The EFS is mounted directly on the pump for accurate dosing rate measurement - All Without Any Time-Consuming Calibration.

How the Auto-degassing System with EFS Operates:

The auto air vent valve bleeds gas and liquid out of the pump chamber. However, pump output is maintained due to the feedback control from the flow sensor.

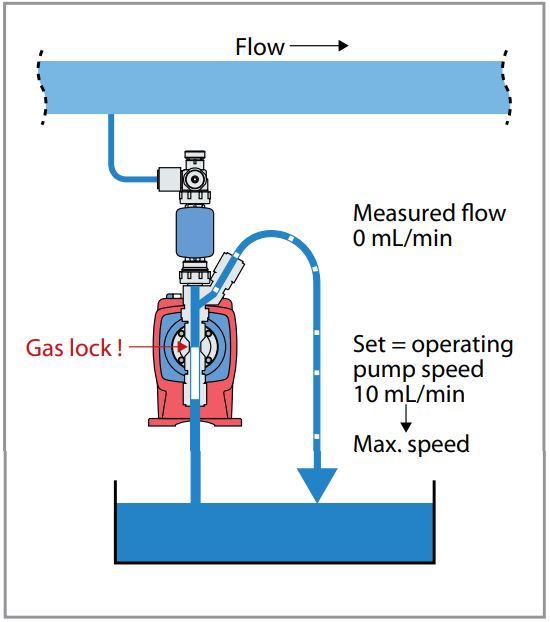

When a large volume of gas enters into the pump chamber, pump output will go to "zero" until the gas bleeds out. The feedback control increases pump speed, reducing the bleed time and quickly repriming the pump.

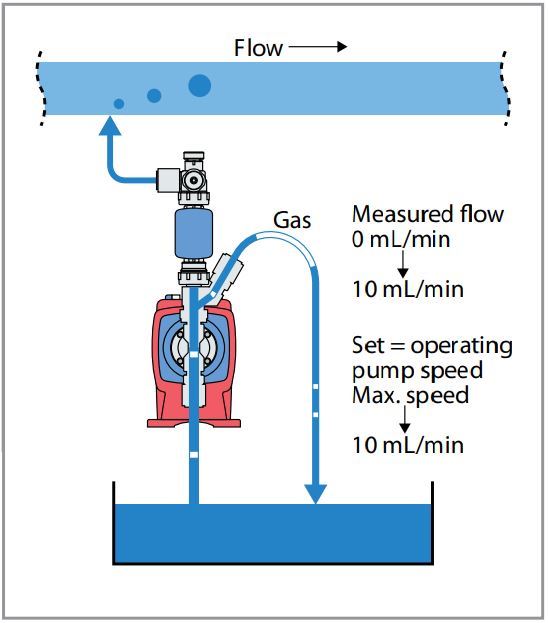

- After the gas has been purged, the EFS sensor will begin to measure flow. Feedback from the sensor controls the pump, slowing it back down so the flow rate meets the set value.

- The EWN-Y electromagnetic pump combined with EFS flow sensor provides accurate real-time control and display of dosing rate. Presence of non-conductive media (i.e. oil) in the flow may generate erroneous readings.

- Set point control allows the desired flow rate to be simply programmed into the pump. Through feedback from the EFS sensor, the pump constantly adjusts its speed to maintain the set dosing rate - even under changing temperature, viscosity or suction and discharge pressure conditions.

- The EWN-Y pump automatically recognizes the EFS sensor when connected and powered. A standard injection check valve is required when discharge-line length is less than 10 feet. An in-line check valve (purchased separately) is required when discharge-line length is over 10 feet.

For more information, please see  Data Sheet

Data Sheet

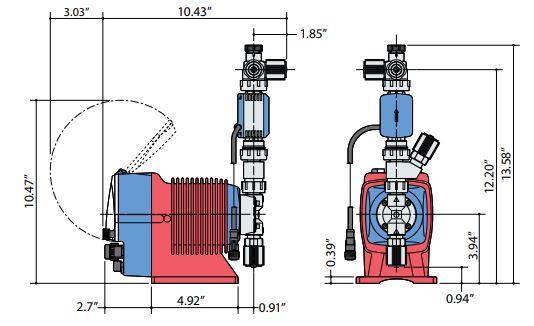

Dimensions: