Koch Filter, 102-701-002, Multi-Pleat XL8 High Capacity 12x24x1" MERV 8 Extended Surface Pleated Panel Filter

Features:

- Upgrade from the standard pleated filter

- MERV 8 and MERV 8-A efficiency

- Low resistance to airflow

- High dust-holding capacity

- Sturdy double-wall frame design

- Moisture-resistant beverage board frame

The Koch Multi-Pleat XL8 is a medium-efficiency extended surface pleated panel filter, engineered to provide higher initial efficiencies and overall superior performance than standard pleated filters. The MultiPleat XL8 carries a MERV 8 and MERV 8-A efficiency by ASHRAE Test Standard 52.2-2017. The MERV 8 and MERV 8-A efficiency provided by the Multi-Pleat XL8 make the filter an excellent upgrade from disposable filters and standard MERV 6 and 7-rated pleated filters. The Multi-Pleat XL8 is designed for applications such as hospitals, laboratories, pharmaceutical plants, commercial office buildings, and any system requiring a higher degree of indoor air quality.

Multi-Pleat XL8 Construction

The Multi-Pleat XL8 media is produced with an optimal blend of highly specialized fibers, developed by Koch Filter specifically for use in extended surface air filters. Developed to deliver a "one of a kind" performance, this specialized media operates on mechanical filtration principles which provide high efficiency, low-pressure drop, and high dust-holding capacity. The Koch Multi-Pleat XL8 maintains a MERV 8 efficiency conditioning steps when tested by ASHRAE Test Standard 52.2-2017 Appendix J. Multi-Pleat XL8 filters provide a combination of efficiency, economy, and excellent overall performance. Multi-Pleat XL8 filters are an excellent choice in applications where filter change schedules are based on preventive maintenance schedules.

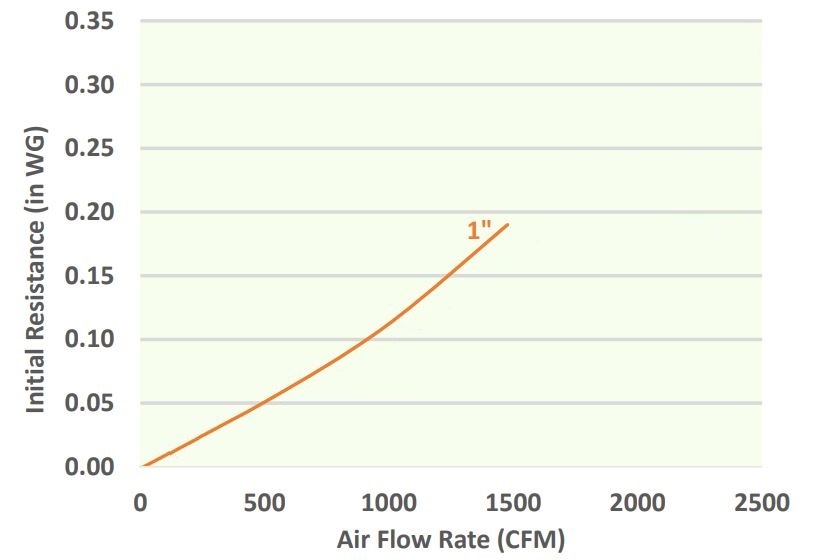

Initial Resistance vs. Air Flow Rate:

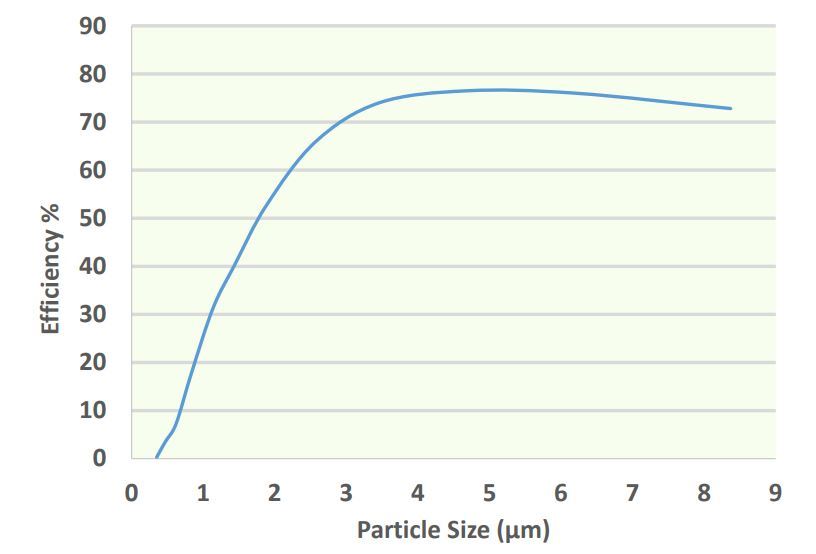

Efficiency by Particle Size:

Engineering Specification:

- General Specifications

- Filters shall be Multi-Pleat XL8 extended surface pleated air filters as manufactured by Koch Filter.

- Filters are classified by Underwriters Laboratories to UL 900 and ULC-S111-07.

- An ISO 9001-registered company manufactures filters

- Filter Material and Construction

- Media shall be 100% synthetic mechanical media treated with Antimicrobial treatment.

- Filters shall have an expanded galvanized steel support grid bonded to the air-exiting side of the filter to maintain pleat uniformity and prevent fluttering.

- The filter frame shall be comprised of a high wet-strength beverage board with a cross member designed to increase filter strength and rigidity. The frame shall be recyclable.

- Filter Performance

- Filters shall be MERV 8 in standard capacity and high capacity configurations when tested by ASHRAE 52.2 Test Standard.

- Filters shall be rated to withstand a continuous operating temperature of up to 200°F.

- Filters shall have a recommended final resistance of 1.0" w.g