A standard calibrator has a one or two-parameter digital display, function switch, and up/down buttons for output level adjustment. Some models include a dial knob for level adjustment, which users consider faster to adjust. Common types of these devices are temperature, multifunction, voltage, gas calibrators, and more.

A Multi-function calibrator combines the functions of voltage and temperature calibrators in a single instrument. Advanced multi-function calibrators can add frequency and pulse source/measure, pH source, pressure measure, or a second channel. Some calibrators include the option of storing test routines for repeated testing. Some users find benefits from the ability to check ground faults, do leakage testing, supply isolated power, and act as a temporary replacement for a faulty loop transmitter.

A temperature calibrator is a device used to determine the accuracy of the reading provided by the temperature-measuring device. It can also check if the readings of these devices are within the specified limits of error and accuracy.

A voltage calibrator is used to check meters, transducers, power supplies, and analog outputs. Some voltage calibrators include a milliamp source and measure capability to do basic checks, common in industrial measurement and control applications.

A pressure calibrator is a high-precision device used to verify the pressure reading of another pressure-measuring tool. The device is also called a pressure standard. The pressure calibrator is considered to provide more accuracy than the instrument being calibrated.

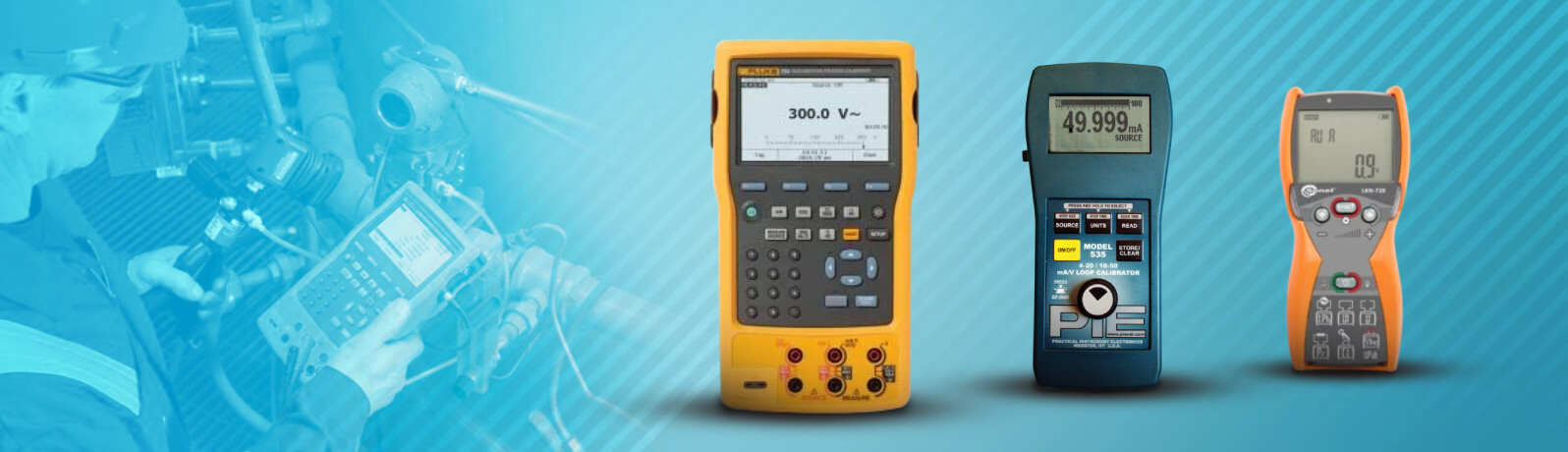

Nowadays, there is a wide range of calibrators used to calibrate industrial process equipment in various applications. Considering what type of calibrator to choose, users should pay attention to the functions the device provides and the additional features offered by the brand.

Choose the needed calibrator on Prime Buy!