- Show results for

- Share

Shims: Types, How To Choose & Use Them. Maudlin Shims

Resource Description

Table Of Contents

Introduction

A shim is a slice of material (e.g. metal, plastic, wood) used to fill the space between two objects or two parts of one object for support, leveling, or adjustment so that they fit better.

Shims are used in a wide range of different applications: in masonry for joint spacing, when adjusting a door’s alignment or leveling a cabinet, in the process of the temporary alignment of heavy things, and the list goes on. People use valve shims, motor shim kits, and more.

In this article, we will consider shim types, figure out how to choose shims, and learn how to use them. You will also find out about shims offered by one of the leading brands.

Types Of Shims

There are various shims types. Let’s consider them in detail.

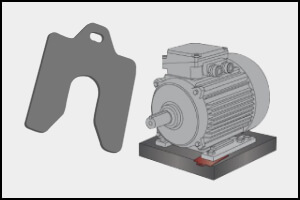

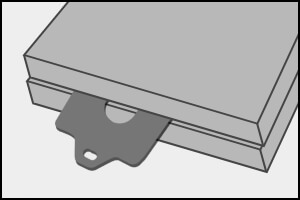

Slotted Shims

They are made with a bolt slot for easy installation. These shims can be fitted around existing bolts and screws or you can use them as spacers. Applications: alignment, leveling, and spacing of machinery, automotive body panels, motors, etc.

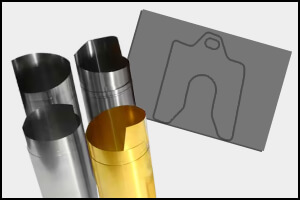

Shim Stock

It is a roll/sheet of thin material (e.g. metal) designed for making custom shims. The material can be cut using scissors/shears. Applications: alignment, leveling, and spacing of machinery in cases where custom shapes/sizes are needed.

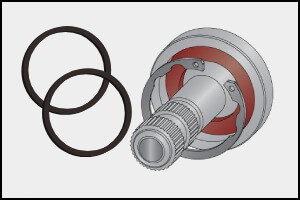

Arbor Shims

These thin discs (like washers) are used to prevent axial movement in assembled components. They are manufactured to specific tolerances to achieve an exact fit.

Applications: alignment and spacing in milling cutters, grinding tools, saws, etc.

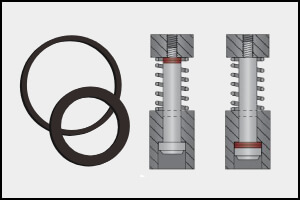

Shim Rings

These are flat and precision machined discs used in housings to form a tight hold on bearings. Often used with lock washers or retaining rings, shim rings prevent axial movement.

Applications: used in molded, stamped, or worn housings if you need to take up play between machine components.

Variable Shims

There are shortening and lengthening variable shims.

Applications: the adjustment of the effective length of shoulder bolts in punch and die assemblies.

How To Choose Shims?

Here are a few things to consider when choosing shims.

1. Application Requirements

Think about your application and consider the following aspects related to shims: function (spacing, alignment, load bearing), movement (static/dynamic loads, vibration, shock, continuous pressure), and conditions (temperature, exposure to chemicals, moisture).

2. Shim Materials

Material impacts the performance of the shim. It’s essential to select the right material for your task.

Metal

Pros: metal shims are strong, durable, and have great heat resistance and dimensional stability.

Cons: they are heavier than some other shims, and corrosion can affect them in moist conditions (a solution to this problem can be using stainless steel shims).

Applications: construction, automotive, and industrial machinery.

Plastic

Pros: plastic shims are lightweight, affordable, and can be used for electrical insulation.

Cons: compared to metal shims, they have lower load capacity and strength as well as limited temperature tolerance, and they may compress over time under pressure.

Applications: aerospace and high-performance machinery.

Wood

Pros: wood shims are versatile and easy to customize (they can be trimmed/shaped), another advantage is their good friction.

Cons: not suitable for applications where they may be exposed to water, extreme heat, inclement weather, etc.

Applications: construction, for precision fitting, minimizing movement.

Laminated Composite

Pros: the combination of different materials (like metal for strength, and plastic for insulation), high strength-to-weight ratio (for applications requiring weight reduction), and low thermal expansion coefficient (to reduce dimensional changes caused by temperature variations).

Cons: the price of the laminated composite shims can be higher than other options, and they may also be less available.

3. Shim Thickness

Shim thickness is essential for the adjustment or spacing you need. To determine the suitable thickness, measure the gap/space that requires adjustment. Notice tolerances/allowances in the assembly. The thickness of the shim should be slightly greater than the measured gap (for fine-tuning). For precise spacing, layer the shims.

4. Temperature Tolerance

For applications where resistance to high temperatures is crucial, choose metal shims (but there are different metals and some cope with this task better, and some are less suitable). The second choice will be plastic. It is better to choose shims made of high-temperature plastics.

5. Load-Bearing Capacity

It is the maximum weight/force shims can withstand without undergoing permanent deformation. When choosing shims for your application, take into account both static and dynamic loads they will experience. For the best load capacity, get metal shims. For lighter loads, opt for plastic shims (nylon shims will be a good option). When choosing shims made of laminated composites, learn about the materials included and decide whether they are good enough for your application.

How To Use Shims?

Let’s figure out how to use shims correctly. This is important to understand for achieving the best results. Follow the steps below.

Step 1. Cleaning the surface.

To remove dirt and/or debris, clean the surface where you are going to install it. You can use a brush and a cleaning solvent (if necessary).

Step 2. Figuring out the shim thickness you need.

With the help of the feeler gages of increasing thicknesses, accurately measure the gap and determine the thickness of the shim needed. Use a micrometer to confirm the thickness of any shims 0.04” or greater. If necessary, determine the existing shim pack thickness using this tool.

Step 3. Choosing the right shims.

- Based on the measurement, choose the best size of the shims for your needs. If necessary, you can stack multiple shims to reach the required height.

- Select the right type of material (for example, stainless steel shims will be perfect for corrosive environments).

- Don’t use corroded or bent shims.

Step 4. Cutting shims from shim stock. (Optional, if you are using shim stock)

Metal shears will do the job if you need to cut simple shapes. For complex shapes, you will need a dedicated press or a stamping kit. Make sure that all edges are deburred.

Step 5. Positioning the shim(s).

Carefully place the shims in the required place. Make sure that the shims don’t move. Then you can continue working.

Maudlin Shims

Maudlin is one of the trusted names when it comes to shims. It is committed to excellence and offers a wide range of top-quality shims that meet demanding industrial requirements. On Prime Buy, choose from Maudlin shims, including slotted shim kits, coil shim stock , shim stock in flat packs, shim stock assortment, as well as key stock, tool wraps, and more.

Maudlin shims are durable and reliable. Maudlin slotted shims boast the tightest tolerances in the industry. Slotted shim kits come in convenient metal boxes.

Coiled shim stock is packaged individually and color-coded with labels for the description of thickness, length, width, as well as material.

Find the best solutions for your application on our website!