- Show results for

- Share

Torque tools. How do you use a torque tool?

Resource Description

Contents:

- What is torque and how is it calculated?

- Types of Torque Tools

- How does a torque wrench work?

- How to store and handle a torque tool?

Your tool case is empty without tool torque. They are usually used for auto repairs, especially calibrated torque tools that are the ideal for such a type of working environment. Torque tools are used to provide a particular torque to fix a nut or bolt. It provides a certain force without risking over-tightening. There are a variety of torque tools to choose from: mechanical or electrical.

What is torque and how it is calculated

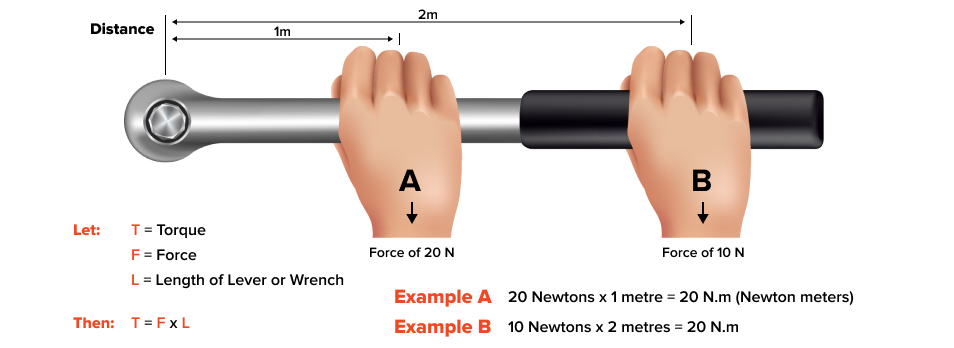

Torque is the rotational equivalent of linear force. In other words, you apply the force and thus cause or change the rotational motion of the object. Torque tools are used to provide a particular torque to fix a nut or bolt. It provides a certain force without risking over-tightening.

There are several factors that affect the magnitude of torque: the amount of force applied, the length of the lever arm that connects the axis to the point where the force is applied, as well as the angle between the force vector and the lever arm.

The formula of torque is length multiplied by force. When torque is enforced to a threaded fixator, it connects the joint together, making a clamp load as the fixator starts expanding.

Types of Torque Tools

|

Torque multiplier is a special mechanism that increases torque in case a torque wrench doesn't have the capacity. This tool is often used if a compressed air-powered impact wrench is unavailable, for example, due to remote locations without power. If long handles can't be used, a torque multiplier will definitely come in handy. |

|

|

|||

|

Torque screwdrivers have special components that ensure tightening to a specified torque. With these tools, you can detect and limit the amount of force applied to a screw. In some applications, torque control is essential. Not enough or too much force may be both damaging for highly sensitive products. That is why, for an array of applications, precision is a must. |

|

|

|||

|

Dial Torque Wrenches is a necessary equipment in torque measurement. It is used for monitoring and identifying torque. There are two types of dial torque wrenches: electronic with an electronic scale-display and mechanical with the indicator that shows the torque measurement on a scale. |

|

|

|||

|

Torque wrench is used for auto repairings by mechanics. It is such a type of wrenches that are not similar to common wrenches. It is used to provide a certain torque for fixing a nut or bolt. More often such types of wrench are also called pipe wrench that provides tightening and untightening fasteners. |

|

|

How to calibrate a torque wrench?

To calibrate a torque wrench is easier than you thought and you can do it following the steps below:

- You need to measure the length of the tool from the area when your hand rests to its square drive.

- Fix the square drive on the vice.

- Add your measurement to the 20 lbs weight to determine the right setting for the tool.

- Hang the 20 lbs weight on the torque wrench at its hand resting position from where you made measurements.

- Fix the tool using the weight.

- When you hear a click, move the weight up to the handle.

- Move the weight down the handle, if you don’t hear the click. Move the weights until you hear one click.

- Point the distance from clicking to not and measure it.

- Multiple the distance by 20 lbs weights.

How to set a torque wrench?

A torque wrench is widely used to tighten a nut or bolt to a certain torque. If you are a vehicle owner, you probably have already used or heard about this tool.

First of all, you have to adjust your torque wrench. After that, you need to follow the next steps:

- Release the tightener, which is at the end of the handle. Turn it in the opposite direction to the movement of a clock's hands. This way, you can easily change the settings of your tool.

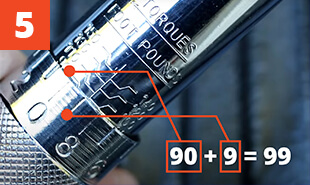

- Determine the torque measurements with the wrench. Usually, there is a set of larger numbers on the tool's body and a set of smaller numbers on the handle.

- To raise or down the torque setting on your wrench, turn the dial. When you turn the handle clockwise, you raise it, and when you turn it counterclockwise - you will lower it.

- To make minor adjustments, turn the dial on the handle. Pay attention that the number goes up as you turn the clockwise.

- To determine total torque, add a smaller number on the handle to the number on a larger hash mark.

- Screw the tightener back into the end of the wrench in order to lock it.

|

|

|

|

|

|

How does a torque wrench work?

Now, let's figure out how to use your torque wrench.

- Take the tool on the handle and put the wrench over the socket.

- Pull the wrench smoothly until you hear a click.

- After that, take the tool off and reset your torque wrench to zero.

|

|

|

|

|

How to store and handle a torque tool?

Pay attention that a torque wrench should be handled with proper care. Avoid dropping the instrument, otherwise, it will be thrown out of calibration and you will have to recalibrate your tool.

Typically, torque wrenches are the most accurate in the center of their range. Another important thing to mention is that you shouldn't store your torque wrench at very high or low torque. Otherwise, your tool will be thrown out of calibration and you won't rely on it. While storing the wrench, stick with approximately 25 percent of the range.

Torque tools can be found in almost every garage, they are important for every vehicle owner. These instruments are widely used in the mechanical and other industries. Use and store your torque wrench properly, follow the manufacturer's instructions, and the tool will be durable for long-term work.