- Show results for

- Share

The Consew 206RB-5 Lockstitch Machine - Changing The Needle

Resource Description

Contents

Introduction

A needle is an important part of your sewing machine and changing it may be a solution if you have problems when sewing. In this article, you will learn about the needle parts and how to change the needle on the Consew 206RB-5 lockstitch machine. You will also find out some information that will help you with your hook timing.

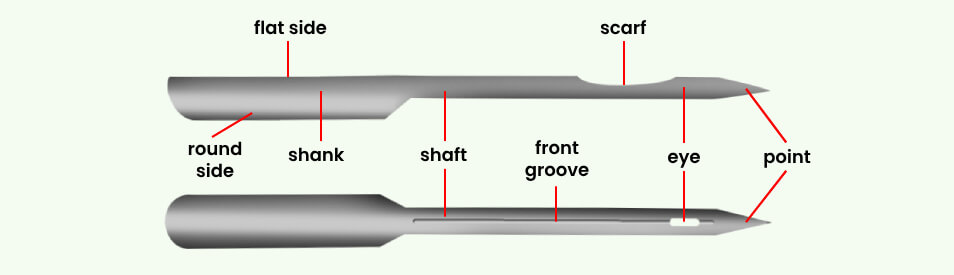

Parts Of A Sewing Machine Needle

Before figuring out how to change your sewing machine needle, let’s quickly consider its parts to understand this process better. Look at the picture below.

Description:

Shank - The part inserted into the sewing machine & clamped into place (typically with the flat side facing the back of the machine).

Shaft - A length of needle enough to carry the thread down through the material to the bobbin.

Front groove - The cupped area along the length of the shaft for the safe passage of the thread through the fabrics.

Scarf - The indentation that allows extra room for the needle to pass close to the shuttle/hook mechanism.

Eye - The hole that holds the needle thread that is carried through the material during stitching.

Point - The needle tip that is designed for the needle to safely pass through the weave/knit without any fiber damage.

How To Change The Needle?

To change your sewing machine needle, follow these simple steps.

1. Raise the hook.

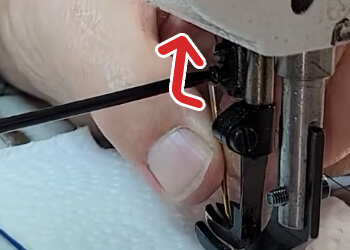

2. Loosen the lower of the two screws (your screwdriver should be on the side of the sewing machine).

3. The needle will drop down, take it.

4. Make sure that the needle is in good condition and doesn’t have a curve to it or any other defect.

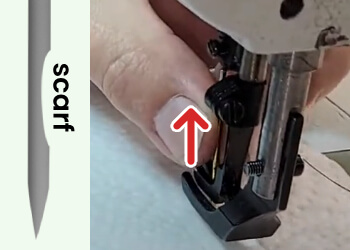

5. Put the needle all the way up inside the needle bar. The scarf (the part above the eye of the needle) should be pointing directly at the main part of your sewing machine, facing the inside of the neck of your machine.

6. Snug the screw back down (not too tightly).

7. Put the thread back through the needle eye (from left to right).

Hook Timing Tips

The timing of a sewing machine is important for achieving even stitches in your fabric and avoiding some problems when sewing (like skips, for example).

Here you can see the results of the right timing (on the left) and the wrong one (on the right):

To advance your timing, here are some useful tips. Follow the steps below.

TIP #1

1. Loosen the screw (the lower one).

2. Now you can change the position/direction of the needle so that the scarf is no longer facing towards the middle of the machine.

This does two things. Firstly, it allows for the hook point to come closer to the needle, because now you’ve changed the scarf. Secondly, it’s going to change the loop, now it comes in another direction, and the hook catches the loop coming another way. Because the hook comes now in another direction, the speed of the hook will change.

So when you have little skips or breaks, to solve the problem, take your needle (make sure it’s pushed all the way up in), turn the scarf a little bit, and see if it fixes your issue.

TIP #2

1. Loosen the screw to loosen the needle.

2. Orient the scarf so it’s in the right position.

3. Drop the needle down a little bit (under a 16th of an inch).

4. Turn the screw. Now the needle is in a lower position.

So you can change the position of the scarf and the height of the needle to improve timing. We hope that the above-mentioned tips will work and you will fix your sewing problems.

Conclusion

Now you are familiar with the parts of your sewing machine needle and understand how to change it on your Consew 206RB-5. After reading this article, you also know how to improve timing, which is necessary to fix some sewing issues.

Consew sewing equipment is reliable and built to last. On Prime Buy, choose from many different Consew sewing machines (industrial Consew sewing machines, Consew leather sewing machines). There are the Consew 7360R-1, Consew CP146RL, Consew CP206RL lockstitch machines, and more.

If you need Consew sewing machine parts, pay attention to Consew servo motors like Consew CSM550-1 (110V), Consew CSM3001 (110 V), etc.

In addition, on our website, you can find various Consew cutting tools (for instance, the Consew CFC-8 and Consew CFC-12 foam and rubber cutting systems).

Get the right solution for your application!