Tek-Trol, 3110B-D-3-CSA-1-HC-1, 0-1000" w.c. Explosion-Proof Piezo Differential Pressure Transmitter with Integrated LCD Display

Features:

- Digital communication HART protocol

- High performance

- High accuracy up to ±0.075%

- It can be used to measure liquid, gas, and steam flow as well as liquid level, density, and pressure

- Various Output: 4-20 mA, digital signals with HART Communication (Modbus RS485)

- Multiple temperature and linearity compensation to improve accuracy

- Fully-sealed and fully isolated silicon pressure sensor

- Superior stainless-steel process flange

- Dual diaphragm overload protection can easily cope with overload tests

- CSA Class I Div I Approved

Applications:

- It is used in various industries like food and beverages, chemical, water, and wastewater industries.

- It is used to measure liquid, Gas, or steam flow as well as liquid level, density, and pressure.

- Measurement of differential pressure across the Flue gas duct.

Tek-Bar 3110B Smart Differential Pressure Transmitter uses the world's advanced single-crystal silicon pressure sensor technology and state-of-the-art encapsulation technology This is a high-performance pressure transmitter with HART communication protocol. It is used to measure liquid, gas, or steam flow, as well as liquid level, density, and pressure. It has an accuracy of up to 0.075% of URL and IP66 water-proof protection.

Measuring Principle

The Tek-Bar 3110B works on the principle of mono-silicon technology. The pressure sensor of the transmitter is located on the top of the metal body, away from the service fluid. This enables mechanical and thermal isolation of the sensor from the fluid in service. When pressure is applied to the diaphragm and the two pairs of piezo resistors, they become stressed and change voltage resistance. This change in resistance is directly proportional to the applied pressure, which is transferred to the transmitter body using lead wires. Built on semiconductor technology, the resistance change (piezoelectric effect) is notably higher than exhibited in standard strain gauges. Therefore, the sensitivity of mono-crystalline sensors is higher than the sensitivity of most other types.

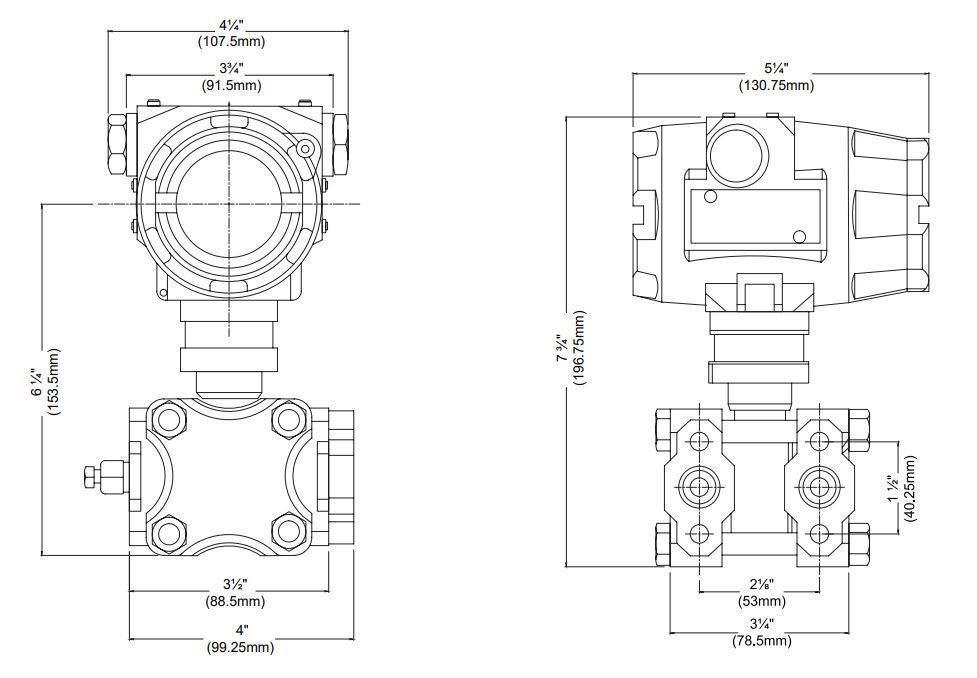

Dimensions: