Scalewatcher, IE2, IE Series Weatherproof Economic Industrial Water Treatment System for up to 2" Pipe

IE2 Includes Only:

- A Scalewatcher® Signal generator

- Signal Cable to create a coil

- Cable Ties

- Mounting screws and wall plugs

- Installation manual, guarantees and performance guide

Applications:

- On energy:

- Hot water boilers

- Steam boilers.

- Chillers.

- Coffee machines.

- Steam sauna's.

- Heat exchangers.

- On water:

- Cooling towers.

- Sprinkler systems.

- Steam boilers.

- Commercial:

- Hotels Sauna's - Spa's

- Swimming pools

- Laundries

- Car wash

- Bakeries Museums

- Hair dressers

- Hospitals

- Restaurants

- Office and apartment buildings

- Industry:

- Paper manufacturers

- Steel manufacturers

- Food and beverage

- Chemical Industry

- Oil production

- Waste water treatment

- Slaughter houses

- Power plants

- Cement factories

- Cable factories

- Plastic molding

- Textile factories

- Municipal water suppliers

- Shipping:

- Merchant marine

- Ferries

- Fishing boats

- Navy

- Cruise ships

Features:

- Maintenance free operation

- Low operation costs

- Completely non invasive, no shut down of production process necessary

- Saves on water, fuel and energy consumption

- Short term payback of investment

- Production levels will rise

- Environmentally friendly.

The Problems

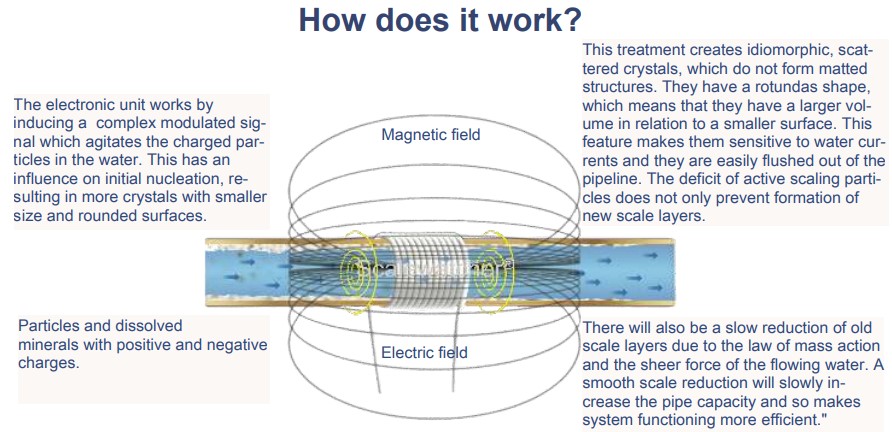

Scaling costs companies each year millions in down time, lost production, early replacement of capital equipment and increased energy usage. Companies are under increasing pressure not only to cut costs and become more efficient, but to do so in environmentally friendly ways. Compounding this problem is the public's increasing focus on environmental concerns and the ever-expanding government legislation in this area.

The Solution

To aid in the solution of this dilemma, Scalewatcher systems have been developed from many years of experience in treating scaling problems throughout the world. They are specifically designed to provide today's industry with an effective proactive and environmentally friendly alternative to chemical scale build-up prevention or mechanical de-scaling. Companies find that solving their scaling problems with a Scalewatcher provides the benefits of scale prevention and reduction of old scale layers without the disadvantages of traditional methods. In addition to preventing scale build-up in boilers and cooling towers, Scalewatcher has also eliminated scaling problems in compressors, water-fed plant and machinery, steam ovens, de-inking plants, liquor lines of paper mills, condensers and air conditioning plants. Lime scale, gypsum and bacterial scaling are examples of deposits which have been treated. The Scalewatcher can be installed and removed from a system without opening the pipe. Making installation, operation and testing very easy.