Features:

- For long heavy starting loads, instant reversing, momentarily overloaded motors, or imported equipment, contact factory or refer to application guidelines RTNKW.

- Multiple motor applications: Due to the high in-rush current required to start a motor (5 to 10 times the normal running current), most applications require sizing the kW of the Rotary Converter 100% larger, or more than the kW rating of the largest motor, or any combination of motors started at exactly the same time. The first motor started, if not running heavily loaded, generates additional 3-phase power back into the circuit.

- Causes no interference to computer, television, or radio equipment.

Baldor Electric/Phase-A-Matic™ Design

The rotary portion of converter is proprietary, custom built to specifications by Baldor Electric, one of the largest and most trusted motor manufacturers in the world. It is a true phase converter and not a modified electric motor as most of competitors use. Many years of testing, changing and developing the converter in conjunction with Baldor's engineers has produced a very simple and trouble-free converter with extremely low idle current and low noise level.

Simplicity of design; uses all soldered connections

Keeping the design exceptionally simple reduces the risk of electrical connection failure to almost zero since these are some of the most common causes of failure.

The Rotor

The Phase-A-Matic™ failure rate is practically zero because the rotors are specifically designed and manufactured for rotary converter use.

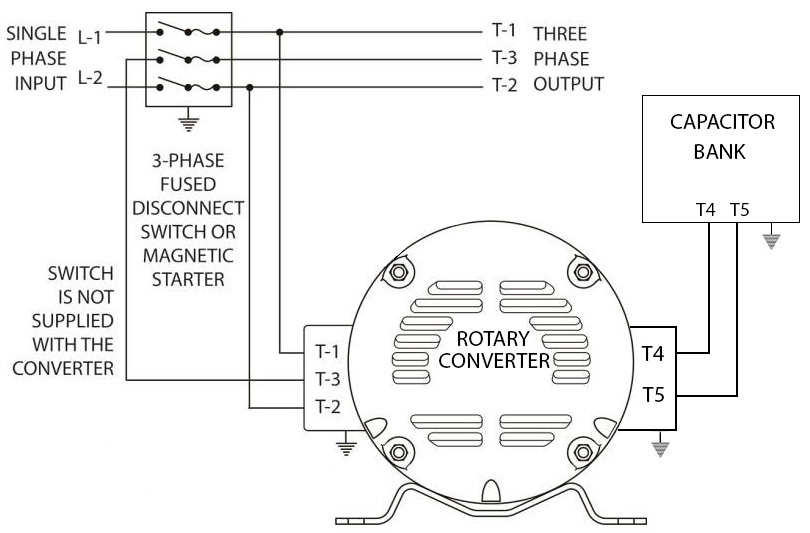

CNC PAC™ Wiring Diagram