LMI, AD912-918HI, Metering Pump 0.21 GPH, Enhanced Controls, O-Ring PTFE/Polyprel, PVC/PVC, AutoPrime Head, 4 Function Valve, 220-240V US Plug

The AD9 series metering pump has a liquid crystal display to indicate pump stroke speed and theoretical flow rate. Applicable for specific chemical pumping application. Control and adjustment for stroke frequency shall be by means of a tactile keypad. Adjustment for stroke length shall be by means of a readily accessible dial knob. A pulse indicator light shall flash green between strokes when pumping. The pump shall be equipped with an on/off button and a low level float switch Input. When the low level sensor registers empty, the low level indicator light shall turn red and the pump shall turn off when it registers an empty level.

Advanced Features - Pulse or 4/20 mA signal input controls frequency, graphical display, manual stroke length control, Frequency manually adjustable when in local control, Pulse multiply/divide functions, 24 V output for remote device, dual low level float switch input, Remote on/off signal input. Outputs include: 4-20 mA, pulse, & Alarm. Remote internal/external mode input. Display configurable to indicate theoretical pump flow. 4FV indicates that the pump is equipped with an LMI Four Function Valve. This diaphragm type, anti-syphon/pressure relief valve is installed on the pump head. It provides anti-syphon protection and aids priming, even under pressure.

AutoPrime™ liquid ends have 3 check valves: suction on the bottom; discharge on the front; auto prime bleed on the top. By design, a repeatable portion of the process fluid continuously bleeds through the top check valve to be returned to the chemical supply. The result is the assurance that any gas in the head is automatically relieved thus eliminating air-binding. Depending on application, output may be reduced up to 50%.

AD912-918HI Includes Only:

- Metering Pump

- Foot Valve

- Ceramic Foot Valve Weight

- Injection Check Valve

- Four Function Valve

- Tube Connection Hardware

Features:

- Push button controls

- Manual knob to control stroke length

- LCD user interface

- Pulse/Analog Input w/ Dual Manual Control

- Low level float switch connection

- Durable and lockable clear cover

- Theoretical flow rate display

- NEMA 4X/IP-65 enclosure

- Industrial grade IP-68 external signal/equipment interface

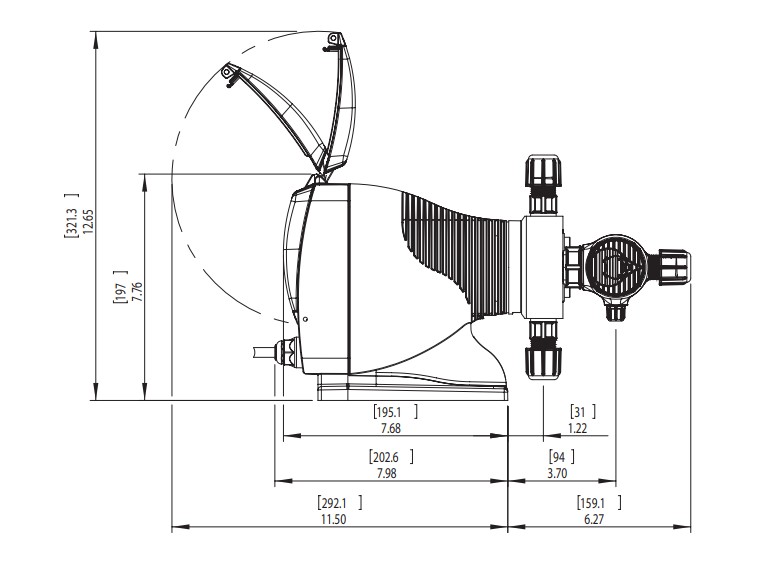

Pump Drawing

LMI recommends flooded suction installations for all high-viscosity fluid applications.

The pump may be mounted maintaining a suction lift of less than 5 ft (1.5 m).