Features:

- Very large detection range

- Intuitive setting of the detection range via pushbutton

- Clearly visible LED for indicating switching status and echo

- With programmable switching output and scalable analog output

- Non-contact detection independent of color, transparency or surface characteristics of the object

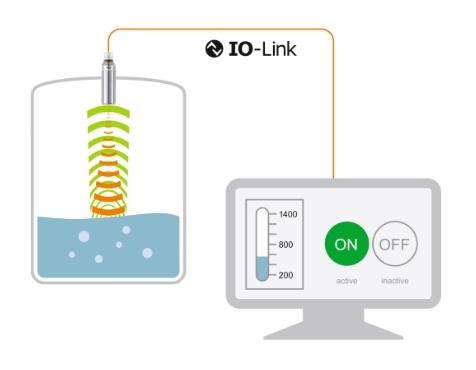

Non-Contact and Continuous Level Measurement

Non-contact level detection of liquids and solids can present a challenge for some technologies. Laser distance measurement systems cannot accurately detect the level of clear liquids. With pinpoint light spots, these systems cannot account for uneven surfaces of solids such as mounding in receiving bins.

Ultrasonic sensors detect liquid and solid levels without direct contact reliably.

- Improve process stability and quality with continuous measurement, monitoring, and feedback

- Reduce cost by eliminating measuring probes

- Increase product quality by eliminating contact contamination

Detection of Transparent Objects

Challenging objects such as transparent bottles, glass, and grid-structured targets are always difficult to detect using optical systems and high-precision cameras are simply too expensive.

Ultrasonic sensors can solve these applications, regardless of color, structure, sound absorption properties, and transparency. It offers an unsurpassed cost-performance ratio compared to other systems.

- Reduce unscheduled downtime due to unreliable switching of other systems

- Improve process stability and quality

- Reduce purchase, installation, and inventory costs

Roll Diameter Measurement

Films, papers and other web materials often have reflective coatings and colors that present a challenge when developing a single solution to measure roll diameter of varied materials. False switching and measuring inaccuracy can result in failure to correctly detect the end of the roll.

Ultrasonic sensors solve this application reliably.

- Reduce unplanned downtime when the roll runs out unexpectedly

- Reduce the time for planned stops by eliminating sensor adjustment between rolls or materials

- Reduce material loss

Detection of Sound-Absorbing Objects

When measuring irregular or sound-absorbing objects, standard diffuse ultrasonic sensors might not receive a return echo. For such applications, retro-reflective sensors can be used. The emitted sound is returned from a defined reflector and received by the sensor. An object is detected when it interrupts the reflected signal regardless of object orientation or surface material.

Ultrasonic Sensor Technology

Ultrasonic sensors detect all sound-reflecting objects and measure the time from transmission to reception of a sound signal. The target's color, transparency and surface reflectivity are irrelevant.

For more information, please see  Data Sheet

Data Sheet