IFM, TD2241, Temperature Transmitter with -10 - 150 Degrees Factory Setting

Features:

- Hygienic design for the requirements of the food and beverage industry

- Fast response dynamics and very short power-on delay time

- Clearly visible numerical display

- High protection and pressure rating

Technology

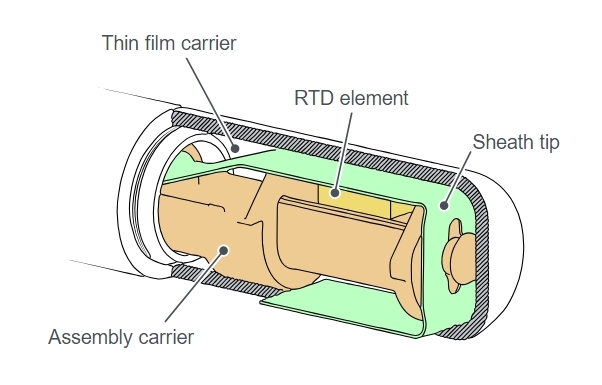

IFM uses a highly engineered construction method. The RTD element is first bonded to a thin film carrier. This reduces the thermal mass of the electrical leads. The film carrier and RTD element is then attached to a specialized assembly carrier. The carrier positions the RTD element into precisely the correct location and preloads the RTD with constant force against the probe’ s inner sheath wall. This allows the RTD element direct and constant controlled contact to the sheath, minimizing the amount of thermal mass separating the RTD element from the process media. The result – fast and repeatable response!

Ordinary RTDs and temperature instruments have the sensing element potted into the tip of the sheath tube. The potting compound acts like an insulator, slowing the heat transfer to the RTD element. Typically, the RTD element location is not controlled, but simply lowered by its lead wires into the sheath and glued into place. Both of these factors lead to poor uniformity, repeatability and response time.

For more information, please see  Data Sheet

Data Sheet