Features:

- Precise measurement of flow, consumption and medium temperature

- High accuracy, repeatability and measurement dynamics

- With switching output, analog output and pulse output

- Clearly readable color display with red/green color change

- No inlet and output pipe lengths required

Magnetic flow meters, commonly known as magmeters, utilize the principles outlined in Faraday's law of induction to accurately measure the flow of conductive liquids in various industrial settings.

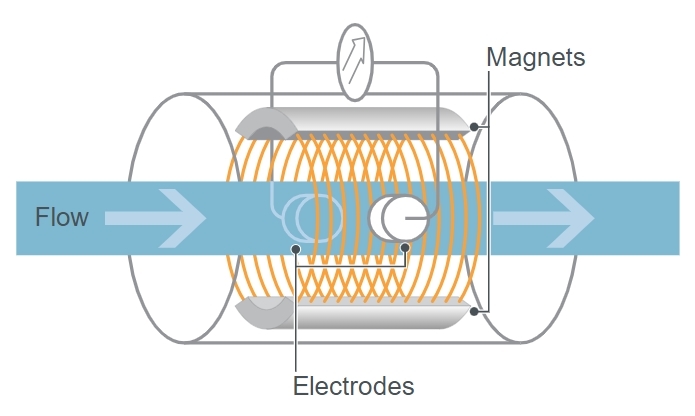

Magnetic-Inductive Principle of Operation

The magnetic-inductive, or magmeter, measuring principle operates according to Faraday's law of induction. Faraday's principle predicts how a magnetic field will react when a voltage is induced in the field.

When a conductive medium flows through a pipe in a magnetic field, the charged particles from the conductive media are directed to an electrode on one side based on the flow direction. Depending on the flow velocity, more or fewer charge carriers are led past the electrode, generating a voltage proportional to the flow velocity or volumetric flow quantity. The voltage is tapped via the measuring electrodes and converted in the evaluation electronics to a usable control signal. As the pipe cross-section is defined, the volumetric flow quantity can be determined exactly.

Farady's Law and Magmeters

When a conductive fluid moves through the magmeter's magnetic field, it induces a voltage. This voltage can then be measured to determine the flow rate of the fluid. Electrodes within the magmeter tap into this voltage. It's then converted within the device's electronics to give a usable control signal that tells us the flow rate of the fluid.

Not every fluid can work with a magmeter. The fluid must be conductive for the device to measure its flow rate. The more conductive the medium, the clearer the reading. Thus, they work was as water flow meters among other liquids.

For more information, please see  Data Sheet

Data Sheet