Features:

- No drips:

- Protect the environment and employees

- Minimize exposure to fluids

- Eliminate costly clean up

- No spills:

- Secure flow shutoff

- The flow stopped and the components were sealed before the coupling can be separated

- An interlock prevents accidental opening

- Helps meet EPA standards

- Better flow:

- Smooth bore

- Simple configuration

- Low-pressure drop

- Ideal for higher-viscosity fluids

- Smaller and lighter:

- Compact and lightweight

- Easy to maneuver

- Fits in tight spaces

- Yet the still drip-free and high flow

Protect both the environment and employees while avoiding costly clean-ups. Conserve every drop of precious commodities. Couplers include a standard built-in swivel.

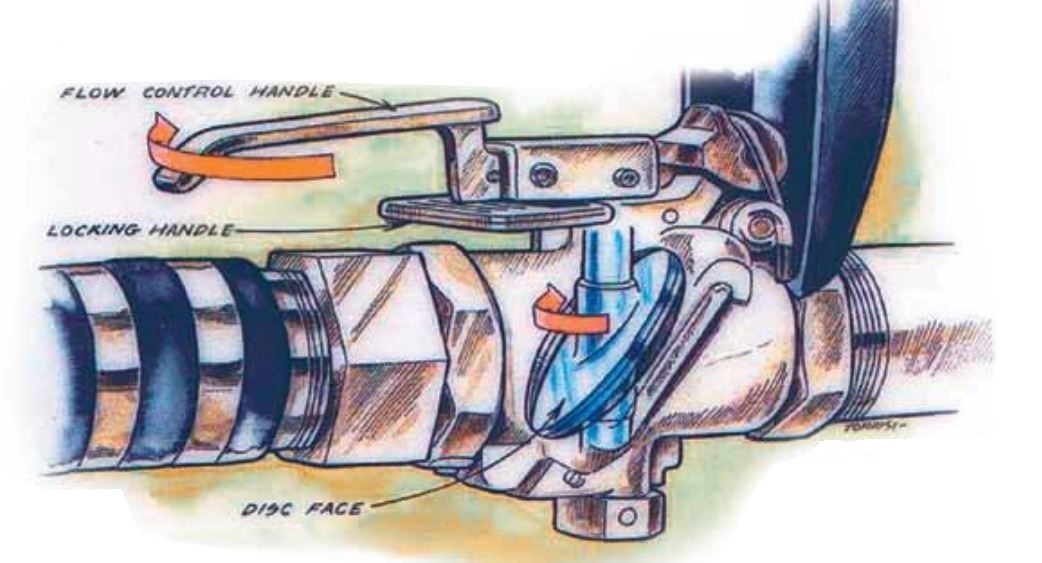

No Drips, No Spills

Dry Link couplings trap fluids before they drip onto the floor or ground. Even small drips can pollute or be dangerous or expensive. Disconnected Dry Link couplings are completely drip-free. Facing discs in the coupler and adapter connect the assembly. The discs swivel to open and close, keeping their faces totally dry.

The flow shut-off mechanism resembles a butterfly valve with very low flow restriction. This design enhances flow while also reducing the risk of internal gunk-ups that can lead to connection malfunctions. A safety interlock prevents accidental opening, and a unique sealing arrangement results in the world's drip-free dry disconnect.

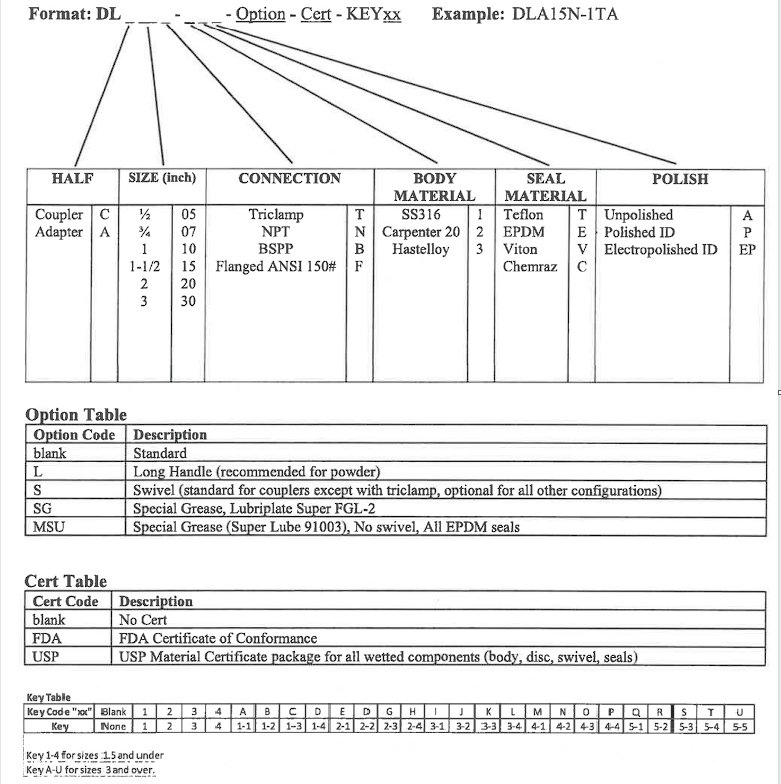

Construction:

No-Hassle Operation

Dry Link is the premier manufacturer of dry-disconnect hose couplings for the chemical, petrochemical, pharmaceutical, biotechnology, and food industries. Ideal for hazardous, high-viscosity, high-flow, and hygienic applications. Patented couplings are up to 50% lighter and more compact than comparable dry-disconnect couplings. Plus, Dry Link couplings use fewer internal components for maximum flow. The modern world depends on substances that could cause harm if they are not stored or handled properly. The only true drip-free coupling on the market. Offers greater protection to workers, eliminates costly clean-ups, and helps you meet EPA standards. Dry Link couplings help reduce greenhouse gases. Dry Link has served domestic and international customers since the early 90s. Dry Link dry-disconnect couplings can be used anywhere a hose is used to transfer fluids, especially where the fluids are hazardous, toxic, corrosive, or flammable.

Keyed couplings are used in batch process plants and manifolds for preventing accidental cross-contamination of fluids. A mechanical interlock allows only a matching coupler and adapter to be connected.

- Prevent accidental connections and cross-contamination.

- Matched sets of couplers and adapters with mechanical keys.

- Keyed units will not latch onto standard non-keyed units.

Maximum Working Pressure:

For one-time field tests only, the maximum joint working pressure may be increased to 1-1/2 times the figures shown. For highly slippery liquids, such as glycol; pressure-temperature ratings are derated than shown here.

Applications:

- Chemical plants

- Sanitary industry

- Pharmaceutical plants

- Cosmetics

- Adhesive manufacturing

- Paint and varnish manufacturing

- Ink manufacturing

- Printing plants

- Soap and detergent manufacturing

- Rubber and plastics manufacturing

- Pulp and paper industry

- Mining

- Automotive manufacturing

- Electric power

- Railroads

- Wastewater treatment plants

- Chemical waste hauling and incineration

- Fiberglass manufacturing

- Agricultural chemicals

- Nuclear industry

- Liquid transfer terminals

- Petrochemical industry

- Circuit board manufacture

- Oils and solvents

- Fertilizer

- Environmental products

Variants of Seal Material:

- Fluoroelastomer (FKM, Viton)

- EPDM

- PTFE (Teflon)

- Perfluoroelastomer (FFKM, Chemraz, Kalrez)

Variants of End Connection:

- Female threaded (NPT or BSPP)

- Butt weld

- Flanged

- Triclover

Variants of Housing Material:

All wetted parts of sanitary couplings are Type 316 stainless steel. For services where severe corrosives are a concern, Dry Link couplings use Alloy 20 (Carpenter 20) or Hastelloy C wetted parts construction.

- Stainless Steel 316 for 1/2" - 4 " Couplings

- Hastelloy C for 1" - 2" Couplings

- Alloy 20 (Carpenter 20) for 2" - 3" Couplings

Dimensions of 1/2" (DN 15), 3/4" (DN 20), 1" (DN 25) and 1-1/2" (DN 40) (SS316), 1"(DN 25), 1-1/2" (DN 40) & 2" (DN 50) (Hastelloy C) Couplings:

For a particular key code, custom-machined matched couplers and adapters can latch only onto each other. Coupler keys are designated as 1C, 2C, 3C, etc., and adapter keys as 1A, 2A, 3A, etc. So a couple stamped with key 1C will connect only with an adapter stamped with key 1A. When ordering, please specify the key code numbers of your choice.

Dimensions of 2" (DN 50), 3" (DN 80) and 4" (DN 100) SS316 and Alloy 20 Housing Couplings:

For 2", 3", and 4" size couplings, each coupler and adapter of the set has an attached key on each side of the body. Coupler keys are designated 1F, 2F, 3F, etc. and the adapter keys 1M, 2M, 3M, etc. These designations are stamped on the keys themselves. Keys are field replaceable.

One key (for example, 5F) is fitted to the left-hand side, and one (for example, 4F) to the right-hand side of a coupler to give the coupler a unique designation 5FL/4FR. The mating adapter for this coupler will have a unique designation of 5ML/4MR. Each combination is given a set code, in this case, set code "T". When ordering, please specify the set code of your choice.

You may request a quote for a specific product or just contact us at any time.