Babbitt International, FS10000-115VAC-S-1.1/2", 1-1/2" Dust Emissions Flow Switch

Features:

- Solid state, no moving parts

- Simple installation and calibration

- No optics or lenses to clean or align

- NEMA 4X enclosure for electronics

- Explosion-proof housing at the probe

- Field adjustable time delay

Applications:

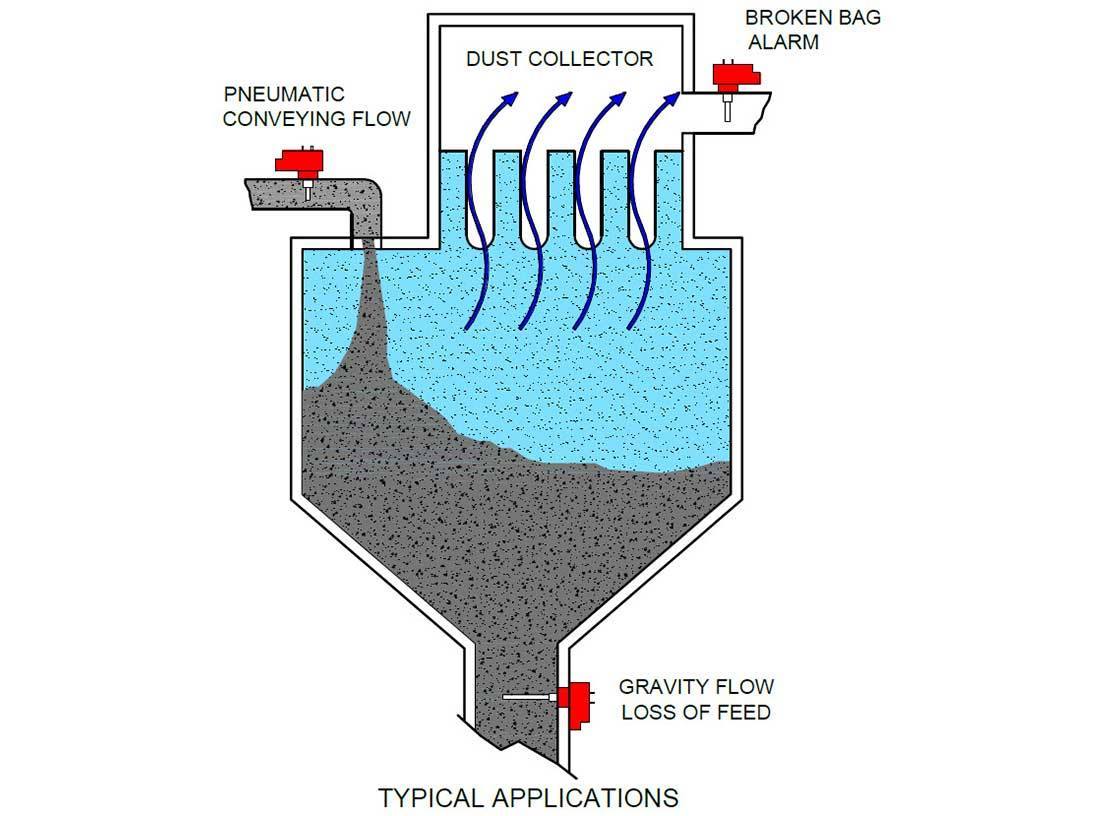

- Detect torn filters in dust collectors

- Fabric or cartridge filter sensing

The FS10000 can detect dust collector emissions before they become visible. When particles collide with the sensing probe, a small electrical charge is transferred to the probe and sensed via the FS10000's proprietary circuitry. This charge transfer is called the triboelectric effect, or "frictional electricity". The FS10000's output is via an onboard relay, which can be used to sound an alarm or perform other control functions.

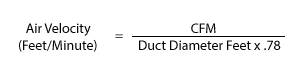

The FS10000 is designed for applications where the velocity is 1800 feet per minute or greater. To calculate velocity when you know the CFM, use the formula below:

All necessary calibration indicators are on the remote-mounted electronics, so a small screwdriver is all you need to calibrate the FS10000. Calibration is performed under a no-flow condition. Each unit has a field adjustable time delay that may be used to ignore nuisance indications or intermittent gaps in the product feed.

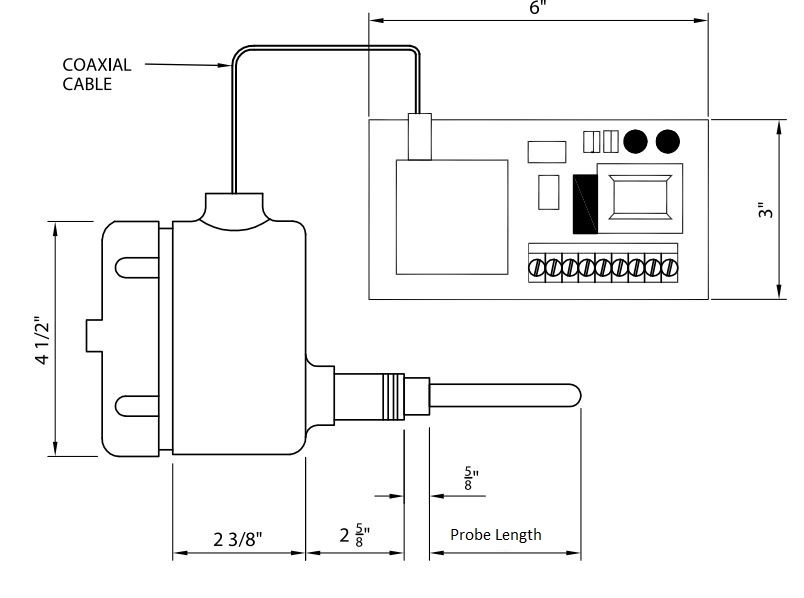

The FS10000 comes complete with the electronic circuit board mounted in a NEMA 4X enclosure, 15 feet of low-noise coaxial cable and connectors, and a 316 stainless steel probe mounted in an explosion-proof enclosure.

The Shield Screen is designed to shield the probe from unwanted electrical noise in the duct that nearby fans or motors may cause. It can also shield the probe from stray static electrical charges created in non-metallic ducts. The Shield Screen bleeds the electrical noise to the ground before it reaches the probe while allowing the dust in the air stream to collide with the sensing probe.

FS10000 Dry Material Flow Switch:

Dimensions: