Alderon, 2005775, Oil Alert Preset Level Sensor, Adjustable Probe, Probe Holder/Float Sensor Assembly, 25' Cable (Sensor Only)

Features:

- (1) Sensor Housing - ABS plastic material with sensor and high level alarm float switch wiring encapsulated in epoxy to ensure a waterproof sensor.

- (2) Pipe Clamp Bracket (not shown) - Located on the back of the sensor housing, used to mount the sensor to a pipe.

- (3) Stainless Steel Pipe Clamps (not shown) - First pipe clamp attaches to the pipe clamp bracket and secures sensor to a pipe at the desired mounting location. The second pipe clamp secures the adjustable probe sensor cable to a pipe at the desired activation level.

- (4) Probes - Two stainless steel probes on the bottom of the sensor housing detect water and oil to operate the pump based on conditions in the monitoring area. The middle probe turns the pump on. The combination of the shortest probe and high level alarm float switch activates a high water or high oil alarm condition.

- (5) Pump Off Adjustable Probe (housing/electrode) - Body is made with 316 stainless steel, the housing and electronics are encapsulated in epoxy, making it completely waterproof. The entire housing is the electrode and turns the pump off.

- (6) Probe Stabilizers - Three probe stabilizers are part of the sensor housing to keep them rigid from inside the housing to the monitoring area for a reliable liquid level sensor.

- (7) Preset Level Sensor Cable - SJEOOW/SJTOOW (UL/CSA), 18 gauge, 5-conductor, FLEXible, and water/oil resistant. Connects the sensor to the terminals on an Alderon™ Oil Alert™ control panel.

- (8) Pump Off Adjustable Probe Cable - SJOOW (UL/CSA), 18 gauge, 2-conductor, FLEXible, and water/oil resistant. The standard length is 48-inches with custom lengths available. Note: both conductors of the adjustable probe cable are connected to the electrode and are terminated inside the sensor housing.

- (9) High Level Alarm Float Switch - SJOOW (UL/CSA), 18 gauge, 2-conductor, FLEXible, and water/oil resistant. Wired to the 5-conductors ensor cable inside the housing, used for indication of an alarm condition.

Application Example

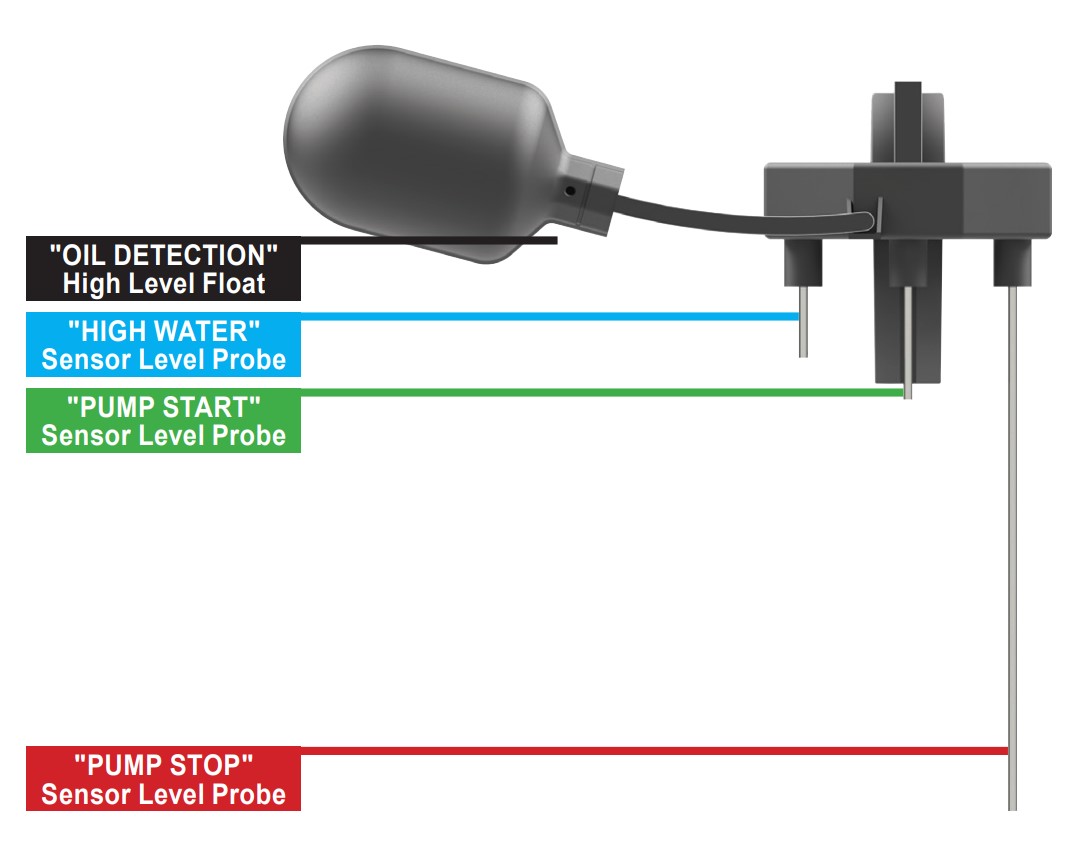

Oil Detection High Level Float - If oil, hydrocarbon, or other harmful substances are floating on top of the water level touching the high water probe while simultaneously activating the high level float switch, then a high oil alarm (oil detected) condition occurs and the pump continuesto run as long as water and not oil is touching the pump start and pump stop probes. The high oil and F1 LEDs will illuminate when activated.High Water Sensor Level Probe - If the water level rises touching the high water probe, a high water alarm condition occurs and the pump continues to run. The alarm condition automatically resets when water is no longer touching the high water probe. The high water and P3 LEDs will illuminate when activated.

Pump Start Sensor Level Probe - As the water level rises touching the pump start probe, the pump will start and continue to run untilthe water level recedes below the pump stop probe to complete the pump cycle. The pump run and P2 LEDs will illuminate when activated.Pump Stop Sensor Level Probe - When the water level is no longer touching this probe, the pump will stop running so the oil layer will not be pumped out of the sump. Oil will float on top of water, so if oil is present and touching this probe, the pump will also stop running. The P1 LED willilluminate when activated.

The Oil Alert™ 48" Suspension Probe Holder/Float Sensor Assembly is a preset level sensor used with Alderon™ Oil Alert™ control panels for the safe operation of pumping, alarming, and monitoring of: elevator sump pits, transformer vaults, and leachate well applications. The Oil Alert™ control panel will activate a pump to remove water from pits in accordance with ASME A17.1, stopping the pump before oil or other harmful substances enter the water supply.

The preset level sensor is mounted at the desired level to a discharge or separate pipe (mounted to side wall) using a stainless steel pipe clamp and then wired to the control panel using low voltage wires. The suspension probe is used for the "pump off" detection, and is mounted in the monitoring area using a stainless steel pipe clamp at the desired activation level.

Use the control panel auxiliary contacts to connect a remote alarm panel for system alarm conditions and connect the alarm panel auxiliary contacts to connect to building automation systems (BAS) and phone dialers for remote notification of alarm conditions.

For more information, please see  Data Sheet and

Data Sheet and  Quick Start Quide

Quick Start Quide